The Steam Engine Change Peoples Perceptions and Use of Time Again

A model of a beam engine featuring James Watt's parallel linkage for double action.[a]

A steam ploughing engine by Kemna

A steam engine is a heat engine that performs mechanical work using steam equally its working fluid. The steam engine uses the force produced past steam pressure to push button a piston back and forth within a cylinder. This pushing strength can be transformed, past a connecting rod and crank, into rotational force for work. The term "steam engine" is by and large applied only to reciprocating engines as just described, not to the steam turbine. Steam engines are external combustion engines,[one] where the working fluid is separated from the combustion products. The ideal thermodynamic cycle used to analyze this process is called the Rankine cycle. In general usage, the term steam engine tin refer to either complete steam plants (including boilers etc.), such as railway steam locomotives and portable engines, or may refer to the piston or turbine machinery alone, every bit in the beam engine and stationary steam engine.

Although steam-driven devices were known as early on as the aeolipile in the offset century Advertizing, with a few other uses recorded in the 16th and 17th century, Thomas Savery is considered the inventor of the first commercially used steam powered device, a steam pump that used steam pressure operating directly on the water. The outset commercially successful engine that could transmit continuous power to a machine was adult in 1712 by Thomas Newcomen. James Watt made a critical improvement in 1764, by removing spent steam to a separate vessel for condensation, greatly improving the corporeality of work obtained per unit of fuel consumed. By the 19th century, stationary steam engines powered the factories of the Industrial Revolution. Steam engines replaced sails for ships on paddle steamers, and steam locomotives operated on the railways.

Reciprocating piston type steam engines were the dominant source of ability until the early 20th century, when advances in the design of electric motors and internal combustion engines resulted in the gradual replacement of steam engines in commercial usage. Steam turbines replaced reciprocating engines in power generation, due to lower cost, college operating speed, and higher efficiency.[2]

History [edit]

Early experiments [edit]

The first recorded rudimentary steam-powered "engine" was the aeolipile described by Hero of Alexandria, a Greek mathematician and engineer in Roman Arab republic of egypt in the offset century Advertisement.[3] In the post-obit centuries, the few steam-powered "engines" known were, like the aeolipile,[4] essentially experimental devices used by inventors to demonstrate the backdrop of steam. A rudimentary steam turbine device was described by Taqi al-Din[5] in Ottoman Egypt in 1551 and by Giovanni Branca[6] in Italy in 1629.[7] The Spanish inventor Jerónimo de Ayanz y Beaumont received patents in 1606 for 50 steam-powered inventions, including a water pump for draining inundated mines.[viii] Denis Papin, a Huguenot, did some useful work on the steam digester in 1679, and first used a piston to raise weights in 1690.[ix]

Pumping engines [edit]

The first commercial steam-powered device was a h2o pump, developed in 1698 by Thomas Savery.[10] Information technology used condensing steam to create a vacuum which raised water from below and then used steam pressure to raise it higher. Small engines were effective though larger models were problematic. They had a very limited lift peak and were prone to boiler explosions. Savery's engine was used in mines, pumping stations and supplying h2o to h2o wheels powering cloth machinery.[11] Savery'due south engine was of low toll. Bento de Moura Portugal introduced an improvement of Savery's construction "to render it capable of working itself", as described by John Smeaton in the Philosophical Transactions published in 1751.[12] It continued to be manufactured until the late 18th century.[13] At least ane engine was still known to exist operating in 1820.[fourteen]

Piston steam engines [edit]

The first commercially successful engine that could transmit continuous power to a automobile was the atmospheric engine, invented past Thomas Newcomen around 1712.[b] [sixteen] It improved on Savery'due south steam pump, using a piston as proposed past Papin. Newcomen'due south engine was relatively inefficient, and generally used for pumping h2o. It worked by creating a partial vacuum by condensing steam under a piston within a cylinder. It was employed for draining mine workings at depths originally impractical using traditional ways, and for providing reusable water for driving waterwheels at factories sited abroad from a suitable "head". H2o that passed over the bike was pumped up into a storage reservoir above the wheel.[17] [18] In 1780 James Pickard patented the use of a flywheel and crankshaft to provide rotative motion from an improved Newcomen engine.[19]

In 1720, Jacob Leupold described a two-cylinder high-force per unit area steam engine.[20] The invention was published in his major work "Theatri Machinarum Hydraulicarum".[21] The engine used two heavy pistons to provide motion to a water pump. Each piston was raised by the steam pressure level and returned to its original position by gravity. The two pistons shared a common 4-way rotary valve connected directly to a steam boiler.

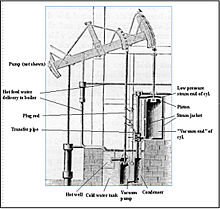

Early Watt pumping engine

The next major step occurred when James Watt developed (1763–1775) an improved version of Newcomen'south engine, with a separate condenser. Boulton and Watt'south early on engines used half as much coal as John Smeaton's improved version of Newcomen'southward.[22] Newcomen's and Watt's early engines were "atmospheric". They were powered by air pressure pushing a piston into the partial vacuum generated by condensing steam, instead of the force per unit area of expanding steam. The engine cylinders had to be large because the only usable force interim on them was atmospheric pressure.[17] [23]

Watt developed his engine further, modifying it to provide a rotary motion suitable for driving machinery. This enabled factories to exist sited away from rivers, and accelerated the footstep of the Industrial Revolution.[23] [17] [24]

High-pressure engines [edit]

The meaning of high pressure, together with an actual value above ambience, depends on the era in which the term was used. For early use of the term Van Reimsdijk[25] refers to steam beingness at a sufficiently high pressure level that it could be exhausted to temper without reliance on a vacuum to enable information technology to perform useful piece of work. Ewing 1894, p. 22 states that Watt'southward condensing engines were known, at the fourth dimension, every bit depression force per unit area compared to high pressure level, non-condensing engines of the same period.

Watt'south patent prevented others from making loftier force per unit area and compound engines. Shortly after Watt'due south patent expired in 1800, Richard Trevithick and, separately, Oliver Evans in 1801[24] [26] introduced engines using high-pressure steam; Trevithick obtained his high-pressure engine patent in 1802,[27] and Evans had made several working models earlier then.[28] These were much more powerful for a given cylinder size than previous engines and could be made small plenty for transport applications. Thereafter, technological developments and improvements in manufacturing techniques (partly brought about past the adoption of the steam engine equally a ability source) resulted in the design of more efficient engines that could exist smaller, faster, or more than powerful, depending on the intended application.[17]

The Cornish engine was developed by Trevithick and others in the 1810s.[29] It was a compound cycle engine that used high-pressure level steam expansively, and then condensed the depression-pressure level steam, making it relatively efficient. The Cornish engine had irregular motility and torque though the cycle, limiting it mainly to pumping. Cornish engines were used in mines and for h2o supply until the belatedly 19th century.[30]

Horizontal stationary engine [edit]

Early on builders of stationary steam engines considered that horizontal cylinders would be subject to excessive clothing. Their engines were therefore arranged with the piston centrality in vertical position. In fourth dimension the horizontal organization became more popular, allowing compact, but powerful engines to exist fitted in smaller spaces.

The meridian of the horizontal engine was the Corliss steam engine, patented in 1849, which was a four-valve counter period engine with carve up steam admission and frazzle valves and automatic variable steam cutoff. When Corliss was given the Rumford Medal, the committee said that "no i invention since Watt'southward time has then enhanced the efficiency of the steam engine".[31] In addition to using 30% less steam, information technology provided more uniform speed due to variable steam cut off, making information technology well suited to manufacturing, especially cotton spinning.[17] [24]

Road vehicles [edit]

Steam powered road-locomotive from England

The kickoff experimental route-going steam-powered vehicles were congenital in the late 18th century, but it was non until afterwards Richard Trevithick had developed the use of high-pressure steam, around 1800, that mobile steam engines became a practical proposition. The first half of the 19th century saw great progress in steam vehicle design, and by the 1850s it was becoming viable to produce them on a commercial basis. This progress was dampened by legislation which limited or prohibited the use of steam-powered vehicles on roads. Improvements in vehicle technology continued from the 1860s to the 1920s. Steam route vehicles were used for many applications. In the 20th century, the rapid development of internal combustion engine engineering led to the demise of the steam engine equally a source of propulsion of vehicles on a commercial ground, with relatively few remaining in utilise across the Second Globe War. Many of these vehicles were acquired by enthusiasts for preservation, and numerous examples are still in existence. In the 1960s, the air pollution bug in California gave rise to a brief menstruation of interest in developing and studying steam-powered vehicles as a possible ways of reducing the pollution. Apart from interest by steam enthusiasts, the occasional replica vehicle, and experimental engineering, no steam vehicles are in product at present.

Marine engines [edit]

About the end of the 19th century, compound engines came into widespread apply. Compound engines wearied steam into successively larger cylinders to suit the higher volumes at reduced pressures, giving improved efficiency. These stages were chosen expansions, with double- and triple-expansion engines being common, peculiarly in shipping where efficiency was important to reduce the weight of coal carried.[17] Steam engines remained the ascendant source of power until the early 20th century, when advances in the design of the steam turbine, electrical motors and internal combustion engines gradually resulted in the replacement of reciprocating (piston) steam engines, with merchant shipping relying increasingly upon diesel engines, and warships on the steam turbine.[17] [2]

Steam locomotives [edit]

As the development of steam engines progressed through the 18th century, various attempts were made to apply them to route and railway utilise.[32] In 1784, William Murdoch, a Scottish inventor, built a model steam road locomotive.[33] An early working model of a steam rail locomotive was designed and constructed by steamboat pioneer John Fitch in the United states probably during the 1780s or 1790s.[34] His steam locomotive used interior bladed wheels[ description needed ] guided by rails or tracks.

The commencement total-scale working railway steam locomotive was built by Richard Trevithick in the Great britain and, on 21 February 1804, the world's first railway journeying took place as Trevithick's unnamed steam locomotive hauled a railroad train forth the tramway from the Pen-y-darren ironworks, virtually Merthyr Tydfil to Abercynon in south Wales.[32] [35] [36] The pattern incorporated a number of important innovations that included using loftier-pressure steam which reduced the weight of the engine and increased its efficiency. Trevithick visited the Newcastle area afterward in 1804 and the colliery railways in north-east England became the leading centre for experimentation and development of steam locomotives.[37]

Trevithick continued his own experiments using a trio of locomotives, concluding with the Catch Me Who Can in 1808. Only four years afterwards, the successful twin-cylinder locomotive Salamanca by Matthew Murray was used past the edge railed rack and pinion Middleton Railway.[38] In 1825 George Stephenson built the Locomotion for the Stockton and Darlington Railway. This was the kickoff public steam railway in the world and then in 1829, he built The Rocket which was entered in and won the Rainhill Trials.[39] The Liverpool and Manchester Railway opened in 1830 making exclusive employ of steam power for both rider and freight trains.

Steam locomotives continued to exist manufactured until the belatedly twentieth century in places such as China and the quondam East Frg (where the DR Grade 52.fourscore was produced).[40]

Steam turbines [edit]

The final major evolution of the steam engine pattern was the use of steam turbines starting in the late part of the 19th century. Steam turbines are generally more than efficient than reciprocating piston blazon steam engines (for outputs above several hundred horsepower), take fewer moving parts, and provide rotary power direct instead of through a connecting rod organization or similar means.[41] Steam turbines virtually replaced reciprocating engines in electricity generating stations early on in the 20th century, where their efficiency, college speed appropriate to generator service, and smooth rotation were advantages. Today nigh electric power is provided by steam turbines. In the U.s.a., 90% of the electrical power is produced in this manner using a variety of estrus sources.[two] Steam turbines were extensively practical for propulsion of large ships throughout almost of the 20th century.

Present development [edit]

Although the reciprocating steam engine is no longer in widespread commercial use, various companies are exploring or exploiting the potential of the engine as an alternative to internal combustion engines. The company Energiprojekt AB in Sweden has fabricated progress in using modern materials for harnessing the power of steam. The efficiency of Energiprojekt'due south steam engine reaches some 27–30% on high-pressure engines. It is a single-pace, 5-cylinder engine (no chemical compound) with superheated steam and consumes approx. four kg (viii.8 lb) of steam per kWh.[42] [ failed verification ]

Components and accessories of steam engines [edit]

There are two fundamental components of a steam plant: the boiler or steam generator, and the "motor unit", referred to itself equally a "steam engine". Stationary steam engines in fixed buildings may have the banality and engine in separate buildings some distance apart. For portable or mobile use, such equally steam locomotives, the two are mounted together.[43] [44]

The widely used reciprocating engine typically consisted of a bandage-iron cylinder, piston, connecting rod and beam or a crank and flywheel, and miscellaneous linkages. Steam was alternately supplied and wearied by one or more than valves. Speed command was either automatic, using a governor, or past a transmission valve. The cylinder casting contained steam supply and exhaust ports.

Engines equipped with a condenser are a separate blazon than those that exhaust to the atmosphere.

Other components are often present; pumps (such as an injector) to supply water to the boiler during performance, condensers to recirculate the water and recover the latent heat of vaporisation, and superheaters to raise the temperature of the steam above its saturated vapour bespeak, and diverse mechanisms to increase the draft for fireboxes. When coal is used, a chain or screw stoking machinery and its bulldoze engine or motor may be included to move the fuel from a supply bin (bunker) to the firebox.[45]

Heat source [edit]

The heat required for boiling the water and raising the temperature of the steam can be derived from various sources, most commonly from called-for flammable materials with an appropriate supply of air in a closed infinite (due east.g., combustion bedroom, firebox, furnace). In the case of model or toy steam engines and a few full scale cases, the heat source can be an electrical heating element.

Boilers [edit]

Boilers are pressure vessels that incorporate h2o to be boiled, and features that transfer the heat to the water as effectively as possible.

The two most common types are:

- H2o-tube banality

- Water is passed through tubes surrounded by hot gas.

- Fire-tube banality

- Hot gas is passed through tubes immersed in h2o, the same water also circulates in a water jacket surrounding the firebox and, in high-output locomotive boilers, also passes through tubes in the firebox itself (thermic syphons and security circulators).

Burn-tube boilers were the master type used for early on high-pressure steam (typical steam locomotive practice), but they were to a large extent displaced past more economical h2o tube boilers in the late 19th century for marine propulsion and large stationary applications.

Many boilers raise the temperature of the steam after information technology has left that part of the boiler where information technology is in contact with the water. Known as superheating it turns 'wet steam' into 'superheated steam'. It avoids the steam condensing in the engine cylinders, and gives a significantly college efficiency.[46] [47]

Motor units [edit]

In a steam engine, a piston or steam turbine or any other similar device for doing mechanical work takes a supply of steam at loftier pressure and temperature and gives out a supply of steam at lower pressure and temperature, using as much of the difference in steam energy as possible to do mechanical piece of work.

These "motor units" are oftentimes chosen 'steam engines' in their ain correct. Engines using compressed air or other gases differ from steam engines but in details that depend on the nature of the gas although compressed air has been used in steam engines without modify.[47]

Cold sink [edit]

As with all heat engines, the majority of chief energy must be emitted every bit waste heat at relatively low temperature.[48]

The simplest cold sink is to vent the steam to the surroundings. This is frequently used on steam locomotives to avoid the weight and bulk of condensers. Some of the released steam is vented upwardly the chimney then as to increase the draw on the burn, which profoundly increases engine power, but reduces efficiency.

Sometimes the waste heat from the engine is useful itself, and in those cases, very high overall efficiency can be obtained.

Steam engines in stationary ability plants apply surface condensers every bit a cold sink. The condensers are cooled by h2o flow from oceans, rivers, lakes, and oft by cooling towers which evaporate h2o to provide cooling energy removal. The resulting condensed hot water (condensate), is and so pumped support to pressure and sent dorsum to the boiler. A dry-type cooling tower is similar to an automobile radiator and is used in locations where water is plush. Waste material heat can besides exist ejected by evaporative (wet) cooling towers, which apply a secondary external water circuit that evaporates some of flow to the air.

River boats initially used a jet condenser in which cold water from the river is injected into the exhaust steam from the engine. Cooling water and condensate mix. While this was too practical for sea-going vessels, by and large subsequently but a few days of performance the banality would go coated with deposited salt, reducing performance and increasing the risk of a banality explosion. Starting nigh 1834, the use of surface condensers on ships eliminated fouling of the boilers, and improved engine efficiency.[49]

Evaporated water cannot exist used for subsequent purposes (other than rain somewhere), whereas river water can be re-used. In all cases, the steam plant boiler feed water, which must exist kept pure, is kept separate from the cooling water or air.

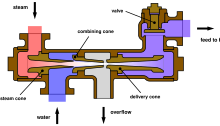

An injector uses a jet of steam to strength water into the boiler. Injectors are inefficient but elementary enough to be suitable for utilise on locomotives.

H2o pump [edit]

Well-nigh steam boilers have a means to supply water whilst at pressure, so that they may be run continuously. Utility and industrial boilers usually use multi-stage centrifugal pumps; yet, other types are used. Some other means of supplying lower-pressure boiler feed water is an injector, which uses a steam jet commonly supplied from the banality. Injectors became pop in the 1850s but are no longer widely used, except in applications such as steam locomotives.[l] It is the pressurization of the h2o that circulates through the steam boiler that allows the water to be raised to temperatures well higher up 100 °C (212 °F) boiling betoken of water at one atmospheric pressure, and by that means to increase the efficiency of the steam bike.

Monitoring and control [edit]

Richard's indicator instrument of 1875. See: Indicator diagram (beneath)

For rubber reasons, most all steam engines are equipped with mechanisms to monitor the boiler, such as a pressure gauge and a sight glass to monitor the h2o level.

Many engines, stationary and mobile, are besides fitted with a governor to regulate the speed of the engine without the need for human interference.

The most useful instrument for analyzing the performance of steam engines is the steam engine indicator. Early versions were in use past 1851,[51] simply the most successful indicator was developed for the high speed engine inventor and manufacturer Charles Porter by Charles Richard and exhibited at London Exhibition in 1862.[24] The steam engine indicator traces on paper the pressure in the cylinder throughout the cycle, which can exist used to spot various problems and calculate adult horsepower.[52] It was routinely used past engineers, mechanics and insurance inspectors. The engine indicator can besides be used on internal combustion engines. See epitome of indicator diagram below (in Types of motor units section).

Governor [edit]

The centrifugal governor was adopted by James Watt for use on a steam engine in 1788 after Watt's partner Boulton saw one on the equipment of a flour manufacturing plant Boulton & Watt were building.[53] The governor could not really hold a gear up speed, because it would presume a new constant speed in response to load changes. The governor was able to handle smaller variations such as those caused by fluctuating rut load to the banality. Besides, there was a tendency for oscillation whenever there was a speed change. As a consequence, engines equipped only with this governor were non suitable for operations requiring constant speed, such as cotton wool spinning.[54] The governor was improved over time and coupled with variable steam cut off, skilful speed control in response to changes in load was attainable near the end of the 19th century.

Engine configuration [edit]

Uncomplicated engine [edit]

In a simple engine, or "single expansion engine" the charge of steam passes through the entire expansion process in an individual cylinder, although a unproblematic engine may take one or more private cylinders.[55] It is then wearied directly into the atmosphere or into a condenser. Every bit steam expands in passing through a high-pressure engine, its temperature drops because no heat is being added to the organization; this is known as adiabatic expansion and results in steam entering the cylinder at high temperature and leaving at lower temperature. This causes a cycle of heating and cooling of the cylinder with every stroke, which is a source of inefficiency.[56]

The ascendant efficiency loss in reciprocating steam engines is cylinder condensation and re-evaporation. The steam cylinder and adjacent metal parts/ports operate at a temperature about halfway between the steam admission saturation temperature and the saturation temperature respective to the exhaust pressure level. As high-force per unit area steam is admitted into the working cylinder, much of the loftier-temperature steam is condensed as water aerosol onto the metal surfaces, significantly reducing the steam available for expansive piece of work. When the expanding steam reaches depression pressure (peculiarly during the exhaust stroke), the previously deposited water droplets that had just been formed inside the cylinder/ports now boil away (re-evaporation) and this steam does no further work in the cylinder.[ citation needed ]

In that location are practical limits on the expansion ratio of a steam engine cylinder, as increasing cylinder area tends to exacerbate the cylinder condensation and re-evaporation issues. This negates the theoretical advantages associated with a high ratio of expansion in an individual cylinder.[57]

Compound engines [edit]

A method to lessen the magnitude of energy loss to a very long cylinder was invented in 1804 by British engineer Arthur Woolf, who patented his Woolf high-pressure chemical compound engine in 1805. In the compound engine, loftier-pressure steam from the banality expands in a high-force per unit area (HP) cylinder and then enters ane or more subsequent lower-pressure (LP) cylinders. The consummate expansion of the steam now occurs across multiple cylinders, with the overall temperature drop inside each cylinder reduced considerably. By expanding the steam in steps with smaller temperature range (within each cylinder) the condensation and re-evaporation efficiency consequence (described higher up) is reduced. This reduces the magnitude of cylinder heating and cooling, increasing the efficiency of the engine. By staging the expansion in multiple cylinders, variations of torque can be reduced.[17] To derive equal work from lower-pressure cylinder requires a larger cylinder book as this steam occupies a greater volume. Therefore, the bore, and in rare cases the stroke, are increased in depression-pressure cylinders, resulting in larger cylinders.[17]

Double-expansion (usually known as compound) engines expanded the steam in two stages. The pairs may be duplicated or the work of the large low-pressure cylinder can be split with one high-force per unit area cylinder exhausting into i or the other, giving a three-cylinder layout where cylinder and piston diameter are about the same, making the reciprocating masses easier to balance.[17]

2-cylinder compounds can be arranged as:

- Cross compounds: The cylinders are side by side.

- Tandem compounds: The cylinders are end to end, driving a mutual connecting rod

- Angle compounds: The cylinders are arranged in a V (usually at a xc° angle) and drive a common creepo.

With two-cylinder compounds used in railway work, the pistons are connected to the cranks equally with a ii-cylinder unproblematic at xc° out of stage with each other (quartered). When the double-expansion group is duplicated, producing a four-cylinder compound, the individual pistons within the group are normally balanced at 180°, the groups being gear up at 90° to each other. In one instance (the start type of Vauclain chemical compound), the pistons worked in the same phase driving a common crosshead and crank, once again set at 90° as for a two-cylinder engine. With the 3-cylinder compound organization, the LP cranks were either set at 90° with the HP 1 at 135° to the other two, or in some cases, all iii cranks were prepare at 120°.[ citation needed ]

The adoption of compounding was common for industrial units, for road engines and near universal for marine engines afterwards 1880; it was non universally popular in railway locomotives where it was ofttimes perceived every bit complicated. This is partly due to the harsh railway operating environment and limited infinite afforded by the loading guess (particularly in United kingdom of great britain and northern ireland, where compounding was never common and not employed after 1930). However, although never in the majority, information technology was popular in many other countries.[58]

Multiple-expansion engines [edit]

An animation of a simplified triple-expansion engine. High-pressure steam (crimson) enters from the banality and passes through the engine, exhausting as low-pressure level steam (blueish), ordinarily to a condenser.

Information technology is a logical extension of the compound engine (described above) to split the expansion into yet more stages to increase efficiency. The event is the multiple-expansion engine. Such engines use either three or four expansion stages and are known equally triple- and quadruple-expansion engines respectively. These engines utilize a serial of cylinders of progressively increasing diameter. These cylinders are designed to divide the work into equal shares for each expansion stage. Equally with the double-expansion engine, if space is at a premium, and so 2 smaller cylinders may be used for the low-pressure level stage. Multiple-expansion engines typically had the cylinders arranged inline, merely diverse other formations were used. In the late 19th century, the Yarrow-Schlick-Tweedy balancing "system" was used on some marine triple-expansion engines. Y-Southward-T engines divided the low-pressure expansion stages between two cylinders, one at each stop of the engine. This allowed the crankshaft to exist better balanced, resulting in a smoother, faster-responding engine which ran with less vibration. This made the four-cylinder triple-expansion engine pop with large passenger liners (such as the Olympic class), but this was ultimately replaced past the virtually vibration-free turbine engine.[ citation needed ] It is noted, however, that triple-expansion reciprocating steam engines were used to bulldoze the World War 2 Liberty ships, by far the largest number of identical ships ever built. Over 2700 ships were built, in the United states, from a British original pattern.[ commendation needed ]

The paradigm in this section shows an blitheness of a triple-expansion engine. The steam travels through the engine from left to right. The valve chest for each of the cylinders is to the left of the corresponding cylinder.[ citation needed ]

Land-based steam engines could exhaust their steam to atmosphere, every bit feed water was normally readily available. Prior to and during World State of war I, the expansion engine dominated marine applications, where high vessel speed was not essential. Information technology was, all the same, superseded by the British invention steam turbine where speed was required, for instance in warships, such equally the dreadnought battleships, and ocean liners. HMSDreadnought of 1905 was the showtime major warship to supercede the proven engineering science of the reciprocating engine with the and so-novel steam turbine.[59]

Types of motor units [edit]

Reciprocating piston [edit]

Double acting stationary engine. This was the common mill engine of the mid 19th century. Note the slide valve with concave, almost "D" shaped, underside.

Schematic Indicator diagram showing the iv events in a double piston stroke. See: Monitoring and control (higher up)

In almost reciprocating piston engines, the steam reverses its direction of flow at each stroke (counterflow), inbound and exhausting from the same end of the cylinder. The consummate engine wheel occupies one rotation of the crank and two piston strokes; the cycle as well comprises iv events – admission, expansion, exhaust, compression. These events are controlled by valves oft working within a steam chest side by side to the cylinder; the valves distribute the steam by opening and endmost steam ports communicating with the cylinder terminate(s) and are driven by valve gear, of which there are many types.[ commendation needed ]

The simplest valve gears give events of fixed length during the engine wheel and often make the engine rotate in only one direction. Many however have a reversing machinery which additionally can provide ways for saving steam as speed and momentum are gained past gradually "shortening the cutoff" or rather, shortening the admission event; this in turn proportionately lengthens the expansion menses. However, as one and the same valve usually controls both steam flows, a short cutoff at admission adversely affects the exhaust and pinch periods which should ideally always exist kept adequately constant; if the frazzle event is besides cursory, the totality of the exhaust steam cannot evacuate the cylinder, choking it and giving excessive compression ("kick back").[60]

In the 1840s and 1850s, there were attempts to overcome this problem by means of various patent valve gears with a split, variable cutoff expansion valve riding on the dorsum of the main slide valve; the latter normally had fixed or limited cutoff. The combined setup gave a off-white approximation of the ideal events, at the expense of increased friction and wear, and the mechanism tended to be complicated. The usual compromise solution has been to provide lap by lengthening rubbing surfaces of the valve in such a fashion as to overlap the port on the admission side, with the consequence that the exhaust side remains open for a longer menstruation after cut-off on the admission side has occurred. This expedient has since been generally considered satisfactory for most purposes and makes possible the use of the simpler Stephenson, Joy and Walschaerts motions. Corliss, and later, poppet valve gears had separate access and exhaust valves driven by trip mechanisms or cams profiled so as to give ideal events; nigh of these gears never succeeded outside of the stationary marketplace due to various other bug including leakage and more delicate mechanisms.[58] [61]

Compression [edit]

Before the frazzle phase is quite complete, the exhaust side of the valve closes, shutting a portion of the exhaust steam inside the cylinder. This determines the compression phase where a absorber of steam is formed confronting which the piston does work whilst its velocity is rapidly decreasing; it moreover obviates the pressure level and temperature shock, which would otherwise be acquired by the sudden access of the high-pressure steam at the beginning of the following bicycle.[ citation needed ]

Lead [edit]

The above effects are further enhanced by providing atomic number 82: every bit was later discovered with the internal combustion engine, information technology has been found advantageous since the late 1830s to advance the admission phase, giving the valve lead then that access occurs a little earlier the end of the exhaust stroke in order to fill up the clearance volume comprising the ports and the cylinder ends (not part of the piston-swept volume) before the steam begins to exert effort on the piston.[62]

Uniflow (or unaflow) engine [edit]

Uniflow engines attempt to remedy the difficulties arising from the usual counterflow cycle where, during each stroke, the port and the cylinder walls volition exist cooled by the passing exhaust steam, whilst the hotter incoming admission steam volition waste material some of its energy in restoring the working temperature. The aim of the uniflow is to remedy this defect and ameliorate efficiency by providing an boosted port uncovered past the piston at the end of each stroke making the steam flow only in one direction. By this means, the simple-expansion uniflow engine gives efficiency equivalent to that of archetype compound systems with the added advantage of superior part-load operation, and comparable efficiency to turbines for smaller engines below one thou horsepower. However, the thermal expansion slope uniflow engines produce along the cylinder wall gives applied difficulties.[ citation needed ].

Turbine engines [edit]

A steam turbine consists of one or more than rotors (rotating discs) mounted on a drive shaft, alternating with a series of stators (static discs) fixed to the turbine casing. The rotors have a propeller-like arrangement of blades at the outer edge. Steam acts upon these blades, producing rotary move. The stator consists of a similar, but fixed, series of blades that serve to redirect the steam flow onto the next rotor phase. A steam turbine often exhausts into a surface condenser that provides a vacuum. The stages of a steam turbine are typically arranged to extract the maximum potential piece of work from a specific velocity and pressure of steam, giving rise to a series of variably sized high- and low-pressure stages. Turbines are merely efficient if they rotate at relatively high speed, therefore they are usually connected to reduction gearing to drive lower speed applications, such equally a ship's propeller. In the vast majority of large electric generating stations, turbines are directly connected to generators with no reduction gearing. Typical speeds are 3600 revolutions per minute (RPM) in the United States with 60 Hertz power, and 3000 RPM in Europe and other countries with 50 Hertz electric power systems. In nuclear power applications, the turbines typically run at half these speeds, 1800 RPM and 1500 RPM. A turbine rotor is besides but capable of providing power when rotating in 1 direction. Therefore, a reversing stage or gearbox is unremarkably required where power is required in the contrary management.[ commendation needed ]

Steam turbines provide direct rotational force and therefore do not require a linkage mechanism to catechumen reciprocating to rotary motion. Thus, they produce smoother rotational forces on the output shaft. This contributes to a lower maintenance requirement and less wear on the machinery they power than a comparable reciprocating engine.[ citation needed ]

The primary apply for steam turbines is in electricity generation (in the 1990s nearly ninety% of the world's electric production was past use of steam turbines)[2] notwithstanding the recent widespread application of large gas turbine units and typical combined cycle power plants has resulted in reduction of this percentage to the lxxx% authorities for steam turbines. In electricity production, the high speed of turbine rotation matches well with the speed of modern electric generators, which are typically direct continued to their driving turbines. In marine service, (pioneered on the Turbinia), steam turbines with reduction gearing (although the Turbinia has direct turbines to propellers with no reduction gearbox) dominated large ship propulsion throughout the late 20th century, being more efficient (and requiring far less maintenance) than reciprocating steam engines. In recent decades, reciprocating Diesel engines, and gas turbines, take well-nigh entirely supplanted steam propulsion for marine applications.[ citation needed ]

Nearly all nuclear power plants generate electricity by heating water to provide steam that drives a turbine continued to an electrical generator. Nuclear-powered ships and submarines either utilize a steam turbine directly for main propulsion, with generators providing auxiliary ability, or else employ turbo-electric transmission, where the steam drives a turbo generator set up with propulsion provided by electric motors. A limited number of steam turbine railroad locomotives were manufactured. Some non-condensing direct-drive locomotives did come across with some success for long booty freight operations in Sweden and for express passenger work in Great britain, but were not repeated. Elsewhere, notably in the Us, more avant-garde designs with electric transmission were built experimentally, but not reproduced. It was found that steam turbines were not ideally suited to the railroad environment and these locomotives failed to oust the classic reciprocating steam unit in the way that mod diesel and electric traction has done.[ commendation needed ]

Oscillating cylinder steam engines [edit]

An oscillating cylinder steam engine is a variant of the elementary expansion steam engine which does not crave valves to direct steam into and out of the cylinder. Instead of valves, the entire cylinder rocks, or oscillates, such that 1 or more holes in the cylinder line up with holes in a fixed port face or in the pivot mounting (trunnion). These engines are mainly used in toys and models, considering of their simplicity, just accept also been used in full-size working engines, mainly on ships where their compactness is valued.[63]

Rotary steam engines [edit]

It is possible to use a mechanism based on a pistonless rotary engine such as the Wankel engine in identify of the cylinders and valve gear of a conventional reciprocating steam engine. Many such engines accept been designed, from the fourth dimension of James Watt to the present day, just relatively few were actually built and even fewer went into quantity production; see link at bottom of article for more details. The major trouble is the difficulty of sealing the rotors to make them steam-tight in the face of clothing and thermal expansion; the resulting leakage made them very inefficient. Lack of expansive working, or any means of control of the cutoff, is also a serious problem with many such designs.[ citation needed ]

Past the 1840s, it was articulate that the concept had inherent bug and rotary engines were treated with some derision in the technical press. However, the arrival of electricity on the scene, and the obvious advantages of driving a dynamo direct from a high-speed engine, led to something of a revival in involvement in the 1880s and 1890s, and a few designs had some limited success.[ citation needed ].

Of the few designs that were manufactured in quantity, those of the Hult Brothers Rotary Steam Engine Visitor of Stockholm, Sweden, and the spherical engine of Beauchamp Tower are notable. Tower's engines were used by the Nifty Eastern Railway to bulldoze lighting dynamos on their locomotives, and by the Admiralty for driving dynamos on board the ships of the Imperial Navy. They were eventually replaced in these niche applications by steam turbines.[ citation needed ]

An aeolipile rotates due to the steam escaping from the arms. No practical utilize was fabricated of this effect.[ commendation needed ]

Rocket type [edit]

The aeolipile represents the use of steam by the rocket-reaction principle, although not for straight propulsion.[ commendation needed ]

In more modern times there has been limited use of steam for rocketry – especially for rocket cars. Steam rocketry works by filling a pressure vessel with hot water at high pressure and opening a valve leading to a suitable nozzle. The drop in pressure immediately boils some of the h2o and the steam leaves through a nozzle, creating a propulsive force.[64]

Ferdinand Verbiest's carriage was powered by an aeolipile in 1679.[ citation needed ]

Safety [edit]

Steam engines possess boilers and other components that are pressure level vessels that comprise a great deal of potential energy. Steam escapes and boiler explosions (typically BLEVEs) tin and have in the by caused great loss of life. While variations in standards may exist in different countries, stringent legal, testing, preparation, care with industry, operation and certification is applied to ensure safety.[ commendation needed ]

Failure modes may include:

- over-pressurisation of the boiler

- insufficient water in the banality causing overheating and vessel failure

- buildup of sediment and calibration which crusade local hot spots, specially in riverboats using dingy feed water

- pressure vessel failure of the boiler due to inadequate construction or maintenance.

- escape of steam from pipework/boiler causing scalding

Steam engines oft possess two independent mechanisms for ensuring that the pressure in the boiler does not become likewise loftier; one may be adjusted past the user, the second is typically designed every bit an ultimate fail-safe. Such safe valves traditionally used a uncomplicated lever to restrain a plug valve in the top of a boiler. Ane stop of the lever carried a weight or spring that restrained the valve against steam pressure. Early valves could exist adjusted by engine drivers, leading to many accidents when a driver attached the valve down to permit greater steam pressure and more ability from the engine. The more than contempo type of rubber valve uses an adjustable jump-loaded valve, which is locked such that operators may not tamper with its adjustment unless a seal is illegally broken. This arrangement is considerably safer.[ citation needed ]

Lead fusible plugs may exist nowadays in the crown of the banality's firebox. If the water level drops, such that the temperature of the firebox crown increases significantly, the lead melts and the steam escapes, alarm the operators, who may so manually suppress the fire. Except in the smallest of boilers the steam escape has little effect on dampening the fire. The plugs are likewise besides small in area to lower steam pressure significantly, depressurizing the boiler. If they were any larger, the volume of escaping steam would itself endanger the crew.[ citation needed ]

Steam cycle [edit]

Flow diagram of the four principal devices used in the Rankine cycle. i) Feedwater pump 2) Boiler or steam generator 3) Turbine or engine four) Condenser; where Q=heat and W=work. Most of the heat is rejected every bit waste.

The Rankine cycle is the fundamental thermodynamic underpinning of the steam engine. The cycle is an arrangement of components equally is typically used for simple power production, and utilizes the phase change of water (boiling water producing steam, condensing frazzle steam, producing liquid h2o)) to provide a practical heat/ability conversion arrangement. The heat is supplied externally to a closed loop with some of the heat added being converted to work and the waste oestrus being removed in a condenser. The Rankine cycle is used in virtually all steam power production applications. In the 1990s, Rankine steam cycles generated nearly 90% of all electrical power used throughout the world, including virtually all solar, biomass, coal and nuclear power plants. It is named later on William John Macquorn Rankine, a Scottish polymath.[ citation needed ]

The Rankine bicycle is sometimes referred to as a applied Carnot cycle because, when an efficient turbine is used, the TS diagram begins to resemble the Carnot cycle. The master difference is that heat addition (in the boiler) and rejection (in the condenser) are isobaric (constant force per unit area) processes in the Rankine cycle and isothermal (constant temperature) processes in the theoretical Carnot wheel. In this bicycle, a pump is used to pressurize the working fluid which is received from the condenser as a liquid not every bit a gas. Pumping the working fluid in liquid grade during the bicycle requires a small fraction of the energy to transport it compared to the energy needed to compress the working fluid in gaseous course in a compressor (equally in the Carnot cycle). The cycle of a reciprocating steam engine differs from that of turbines because of condensation and re-evaporation occurring in the cylinder or in the steam inlet passages.[56]

The working fluid in a Rankine cycle can operate as a closed loop organisation, where the working fluid is recycled continuously, or may be an "open up loop" system, where the frazzle steam is directly released to the temper, and a split source of h2o feeding the boiler is supplied. Normally h2o is the fluid of choice due to its favourable properties, such as non-toxic and unreactive chemistry, abundance, depression toll, and its thermodynamic properties. Mercury is the working fluid in the mercury vapor turbine. Depression boiling hydrocarbons tin can be used in a binary cycle.[ citation needed ]

The steam engine contributed much to the development of thermodynamic theory; all the same, the only applications of scientific theory that influenced the steam engine were the original concepts of harnessing the ability of steam and atmospheric pressure and noesis of backdrop of heat and steam. The experimental measurements made past Watt on a model steam engine led to the development of the separate condenser. Watt independently discovered latent heat, which was confirmed by the original discoverer Joseph Black, who also brash Watt on experimental procedures. Watt was also aware of the modify in the boiling point of water with pressure. Otherwise, the improvements to the engine itself were more mechanical in nature.[xiii] The thermodynamic concepts of the Rankine bike did give engineers the agreement needed to calculate efficiency which aided the development of modern loftier-pressure level and -temperature boilers and the steam turbine.[ citation needed ]

Efficiency [edit]

The efficiency of an engine cycle can exist calculated by dividing the energy output of mechanical piece of work that the engine produces past the energy put into the engine by the burning fuel.[ citation needed ]

The historical measure out of a steam engine'southward energy efficiency was its "duty". The concept of duty was first introduced past Watt in order to illustrate how much more efficient his engines were over the earlier Newcomen designs. Duty is the number of pes-pounds of work delivered by called-for 1 bushel (94 pounds) of coal. The best examples of Newcomen designs had a duty of about 7 1000000, simply most were closer to v one thousand thousand. Watt'due south original low-pressure designs were able to deliver duty as high as 25 meg, just averaged nearly 17. This was a three-fold improvement over the average Newcomen design. Early on Watt engines equipped with high-pressure steam improved this to 65 meg.[65]

No estrus engine tin be more efficient than the Carnot bicycle, in which estrus is moved from a high-temperature reservoir to one at a low temperature, and the efficiency depends on the temperature deviation. For the greatest efficiency, steam engines should be operated at the highest steam temperature possible (superheated steam), and release the waste oestrus at the lowest temperature possible.[ citation needed ]

The efficiency of a Rankine cycle is usually limited by the working fluid. Without the pressure level reaching supercritical levels for the working fluid, the temperature range over which the cycle can operate is small; in steam turbines, turbine entry temperatures are typically 565 °C (the pitter-patter limit of stainless steel) and condenser temperatures are around thirty °C. This gives a theoretical Carnot efficiency of about 63% compared with an actual efficiency of 42% for a mod coal-fired power station. This low turbine entry temperature (compared with a gas turbine) is why the Rankine cycle is ofttimes used equally a bottoming cycle in combined-bicycle gas turbine power stations.[ citation needed ]

One main advantage the Rankine cycle holds over others is that during the compression stage relatively fiddling piece of work is required to drive the pump, the working fluid being in its liquid stage at this point. By condensing the fluid, the work required by the pump consumes just 1% to 3% of the turbine (or reciprocating engine) power and contributes to a much higher efficiency for a existent bicycle. The benefit of this is lost somewhat due to the lower rut addition temperature. Gas turbines, for example, have turbine entry temperatures budgeted 1500 °C. Nonetheless, the efficiencies of bodily big steam cycles and large modernistic simple wheel gas turbines are fairly well matched.[ citation needed ]

In practice, a reciprocating steam engine cycle exhausting the steam to atmosphere will typically have an efficiency (including the boiler) in the range of 1–10%, but with the add-on of a condenser, Corliss valves, multiple expansion, and high steam force per unit area/temperature, information technology may be greatly improved, historically into the range of 10–20%, and very rarely slightly higher.[ commendation needed ]

A modern, large electrical power station (producing several hundred megawatts of electric output) with steam reheat, economizer etc. will achieve efficiency in the mid 40% range, with the most efficient units approaching 50% thermal efficiency.[ commendation needed ]

It is as well possible to capture the waste matter rut using cogeneration in which the waste oestrus is used for heating a lower boiling point working fluid or every bit a heat source for district heating via saturated low-force per unit area steam.[ citation needed ]

-

British equus caballus-drawn fire engine with steam-powered water pump

See also [edit]

- Boyle's law

- Compound locomotive

- Cylinder

- Geared steam locomotive

- History of steam route vehicles

- Lean's Engine Reporter

- List of steam fairs

- Listing of steam museums

- List of steam engineering patents

- Alive steam

- Mechanical stoker

- James Rumsey

- Salomon de Caus

- Steam aircraft

- Steam boat

- Steam car

- Steam crane

- Steam ability during the Industrial Revolution

- Steam shovel

- Steam tractor

- Steam tricycle

- Still engine

- Timeline of steam power

- Traction engine

Notes [edit]

- ^ This model was built by Samuel Pemberton between 1880-1890.

- ^ Landes[15] refers to Thurston's definition of an engine and Thurston's calling Newcomen's the "starting time true engine."

References [edit]

- ^ American Heritage Dictionary of the English Linguistic communication (4th ed.). Houghton Mifflin Company. 2000.

- ^ a b c d Wiser, Wendell H. (2000). Energy resources: occurrence, production, conversion, use. Birkhäuser. p. 190. ISBN978-0-387-98744-6.

- ^ "turbine". Encyclopædia Britannica Online. 18 July 2007.

- ^ "De Architectura": Chapter VI (paragraph two)

from "Ten Books on Architecture" by Vitruvius (1st century BC), published 17, June, 08 [1] accessed 2009-07-07 - ^ Ahmad Y Hassan (1976). Taqi al-Din and Standard arabic Mechanical Engineering, pp. 34–35. Found for the History of Arabic Scientific discipline, Academy of Aleppo.

- ^ "University of Rochester, NY, The growth of the steam engine online history resource, chapter 1". History.rochester.edu. Archived from the original on 24 July 2011. Retrieved iii February 2010.

- ^ Nag 2002, p. 432–.

- ^ Garcia, Nicholas (2007). Mas alla de la Leyenda Negra. Valencia: Universidad de Valencia. pp. 443–54. ISBN978-84-370-6791-nine.

- ^ Hills 1989, pp. 15, xvi, 33.

- ^ Lira, Carl T. (21 May 2013). "The Savery Pump". Introductory Chemical Applied science Thermodynamics. Michigan State University. Retrieved eleven April 2014.

- ^ Hills 1989, pp. 16–20

- ^ "LXXII. An engine for raising water past burn; being on comeback of saver'y construction, to render it capable of working itself, invented by Mr. De Moura of Portugal, F. R. S. Described by Mr. J. Smeaton". Philosophical Transactions of the Regal Society of London. 47: 436–438. 1752. doi:10.1098/rstl.1751.0073. S2CID 186208904.

- ^ a b Landes 1969.

- ^ Jenkins, Ryhs (1971) [Kickoff published 1936]. Links in the History of Engineering and Engineering from Tudor Times. Cambridge: The Newcomen Society at the Cambridge University Printing. ISBN978-0-8369-2167-0. . Collected Papers of Rhys Jenkins, Former Senior Examiner in the British Patent Part.

- ^ Landes 1969, p. 101.

- ^ Chocolate-brown 2002, pp. 60-.

- ^ a b c d e f g h i j Hunter 1985.

- ^ Nuvolari, A; Verspagen, Bart; Tunzelmann, Nicholas (2003). "The Diffusion of the Steam Engine in Eighteenth-Century U.k.. Practical Evolutionary Economics and the Knowledge-based Economy". Eindhoven, The Netherlands: Eindhoven Centre for Innovation Studies (ECIS): 3. (Paper to be presented at 50th Almanac North American Meetings of the Regional Scientific discipline Clan International twenty–22 November 2003)

- ^ Nuvolari, Verspagen & Tunzelmann 2003, p. iv.

- ^ Galloway, Elajah (1828). History of the Steam Engine. London: B. Steill, Paternoster-Row. pp. 23–24.

- ^ Leupold, Jacob (1725). Theatri Machinarum Hydraulicarum. Leipzig: Christoph Zunkel.

- ^ Hunter & Bryant 1991 Duty comparing was based on a carefully conducted trial in 1778.

- ^ a b Rosen, William (2012). The Nigh Powerful Idea in the World: A Story of Steam, Industry and Invention. University of Chicago Press. p. 185. ISBN978-0-226-72634-two.

- ^ a b c d Thomson, Ross (2009). Structures of Modify in the Mechanical Age: Technological Invention in the United States 1790–1865. Baltimore, Md: The Johns Hopkins Academy Press. p. 34. ISBN978-0-8018-9141-0.

- ^ "The Pictorial History of Steam Power" J.T. Van Reimsdijk and Kenneth Brown, Octopus Books Limited 1989, ISBN 0-7064-0976-0, p. 30

- ^ Cowan, Ruth Schwartz (1997), A Social History of American Applied science, New York: Oxford University Printing, p. 74, ISBN978-0-19-504606-9

- ^ Dickinson, Henry Due west; Titley, Arthur (1934). "Chronology". Richard Trevithick, the engineer and the man. Cambridge, England: Cambridge University Press. p. xvi. OCLC 637669420.

- ^ The American Car since 1775, Pub. L. Scott. Baily, 1971, p. 18

- ^ Hunter 1985, pp. 601–628.

- ^ Hunter 1985, p. 601.

- ^ Van Slyck, J.D. (1879). New England Manufacturers and Manufactories. New England Manufacturers and Manufactories. volume 1. Van Slyck. p. 198.

- ^ a b Payton 2004.

- ^ Gordon, Westward.J. (1910). Our Domicile Railways, volume ane. London: Frederick Warne and Co. pp. 7–nine.

- ^ "Nation Park Service Steam Locomotive article with photograph of Fitch Steam model and dates of structure equally 1780–1790". Nps.gov. fourteen February 2002. Retrieved 3 November 2009.

- ^ "Richard Trevithick'due south steam locomotive | Rhagor". Museumwales.air-conditioning.united kingdom of great britain and northern ireland. Archived from the original on 15 April 2011. Retrieved 3 November 2009.

- ^ "Steam train anniversary begins". BBC. 21 February 2004. Retrieved 13 June 2009.

A south Wales town has begun months of celebrations to mark the 200th anniversary of the invention of the steam locomotive. Merthyr Tydfil was the location where, on 21 February 1804, Richard Trevithick took the world into the railway age when he prepare one of his high-pressure steam engines on a local iron principal's tram rails

- ^ Garnett, A.F. (2005). Steel Wheels. Cannwood Press. pp. xviii–19.

- ^ Young, Robert (2000). Timothy Hackworth and the Locomotive (reprint of 1923 ed.). Lewes, UK: the Book Order Ltd.

- ^ Hamilton Ellis (1968). The Pictorial Encyclopedia of Railways. The Hamlyn Publishing Group. pp. 24–30.

- ^ Michael Reimer, Dirk Endisch: Baureihe 52.80 – Dice rekonstruierte Kriegslokomotive, GeraMond, ISBN iii-7654-7101-ane

- ^ Vaclav Smil (2005), Creating the Twentieth Century: Technical Innovations of 1867–1914 and Their Lasting Affect, Oxford University Press, p. 62, ISBN978-0-19-516874-vii , retrieved 3 January 2009

- ^ "Energiprojekt LTD – Biomass power plant, Steam pow". Energiprojekt.com. Archived from the original on 20 August 2008. Retrieved 3 February 2010.

- ^ Hunter 1985, pp. 495–96 Description of the Colt portable engine

- ^ McNeil 1990 See description of steam locomotives

- ^ Jerome, Harry (1934). Mechanization in Manufacture, National Bureau of Economic Research (PDF). pp. 166–67.

- ^ Hills 1989, p. 248.

- ^ a b Peabody 1893, p. 384.

- ^ "Fossil Energy: How Turbine Power Plants Piece of work". Fossil.free energy.gov. Archived from the original on 12 Baronial 2011. Retrieved 25 September 2011.

- ^ Nick Robins, The Coming of the Comet: The Rise and Fall of the Paddle Steamer, Seaforth Publishing, 2012, ISBN ane-4738-1328-X, Affiliate four

- ^ Hunter 1985, pp. 341–43.

- ^ Hunter & Bryant 1991, p. 123, 'The Steam Engine Indicator' Stillman, Paul (1851).

- ^ Walter, John (2008). "The Engine Indicator" (PDF). pp. xxv–xxvi. Archived from the original (PDF) on 10 March 2012.

- ^ Bennett, S. (1979). A History of Control Engineering 1800–1930. London: Peter Peregrinus Ltd. ISBN978-0-86341-047-5.

- ^ Bennett 1979

- ^ Basic Mechanical Technology by Mohan Sen p. 266

- ^ a b Hunter 1985, p. 445.

- ^ "Stirling | Internal Combustion Engine | Cylinder (Engine) | Gratuitous thirty-24-hour interval Trial". Scribd . Retrieved 21 May 2020.

- ^ a b van Riemsdijk, John (1994). Chemical compound Locomotives. Penrhyn, Uk: Atlantic Ship Publishers. pp. two–3. ISBN978-0-906899-61-8.

- ^ Brooks, John. Dreadnought Gunnery at the Boxing of Jutland. p. 14.

- ^ "Backfiring". The Tractor Field Book: With Ability Farm Equipment Specifications. Chicago: Farm Implement News Company. 1928. pp. 108–109 [ 108 ].

- ^ Chapelon 2000, pp. 56–72, 120-.

- ^ Bell, A.Yard. (1950). Locomotives. London: Virtue and Company. pp. 61–63.

- ^ Seaton, A E (1918). Manual of Marine Applied science. London: Charles Griffin. pp. 56–108.

- ^ Steam Rockets Tecaeromax

- ^ John Enys, "Remarks on the Duty of the Steam Engines employed in the Mines of Cornwall at different periods", Transactions of the Establishment of Civil Engineers, Volume iii (xiv January 1840), p. 457

References [edit]

- Brown, Richard (2002). Lodge and Economy in Modern United kingdom 1700-1850. Taylor & Francis. ISBN978-0-203-40252-viii.

- Chapelon, André (2000) [1938]. La locomotive à vapeur [The Steam Locomotive] (in French). Translated past Carpenter, George Westward. Camden Miniature Steam Services. ISBN978-0-9536523-0-3.

- Ewing, Sir James Alfred (1894). The Steam-engine and Other Heat-engines. Cambridge: University Press.

- Hills, Richard L. (1989). Ability from Steam: A history of the stationary steam engine. Cambridge: Cambridge University Press. ISBN978-0-521-34356-5.

- Hunter, Louis C. (1985). A History of Industrial Ability in the United States, 1730–1930. Vol. 2: Steam Ability. Charlottesville: Academy Press of Virginia.

- Hunter, Louis C.; Bryant, Lynwood (1991). A History of Industrial Power in the The states, 1730–1930 . Vol. 3: The Transmission of Power. Cambridge, MA: MIT Press. ISBN978-0-262-08198-6.

- Landes, David Due south. (1969). The Unbound Prometheus: Technological Change and Industrial Evolution in Western Europe from 1750 to the Nowadays. Cambridge, NY: Printing Syndicate of the Academy of Cambridge. ISBN978-0-521-09418-4.

- McNeil, Ian (1990). An Encyclopedia of the History of Applied science . London: Routledge. ISBN978-0-415-14792-7.

- Nag, P. K. (2002). Power Plant Engineering. Tata McGraw-Hill Educational activity. ISBN978-0-07-043599-five.

- Payton, Philip (2004). "Trevithick, Richard (1771–1833)". Oxford Dictionary of National Biography (online ed.). Oxford University Press. doi:10.1093/ref:odnb/27723. (Subscription or U.k. public library membership required.)

- Peabody, Cecil Hobart (1893). Thermodynamics of the Steam-engine and Other Heat-engines. New York: Wiley & Sons.

Further reading [edit]

- Crump, Thomas (2007). A Cursory History of the Age of Steam: From the First Engine to the Boats and Railways.

- Marsden, Ben (2004). Watt's Perfect Engine: Steam and the Age of Invention. Columbia University Press.

- Robinson, Eric H. (March 1974). "The Early on Improvidence of Steam Power". The Journal of Economic History. 34 (1): 91–107. doi:10.1017/S002205070007964X. JSTOR 2116960.

- Rose, Joshua. (1887, reprint 2003) Modernistic Steam Engines

- Stuart, Robert (1824). A Descriptive History of the Steam Engine. London: J. Knight and H. Lacey.

- Thurston, Robert Henry (1878). A History of the Growth of the Steam-engine. The International Scientific Series. New York: D. Appleton and Company. OCLC 16507415.

- Van Riemsdijk, J.T. (1980) Pictorial History of Steam Power.

- Charles Algernon Parsons (1911), The Steam Turbine: The Rede Lecture 1911 (1st ed.), Cambridge: Cambridge University Press, Wikidata Q19099885 (lecture)

External links [edit]

- Animated engines – Illustrates a diversity of engines

- Howstuffworks – "How Steam Engines Piece of work"

- Video of the 1900 steam engine aboard paddle steamer Unterwalden

berrickbressibity.blogspot.com

Source: https://en.wikipedia.org/wiki/Steam_engine